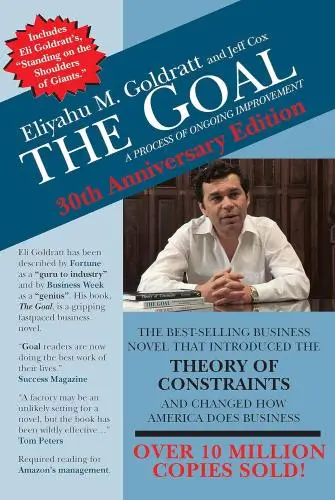

The Goal

A Process of Ongoing Improvement

What is The Goal about?

The Goal by Eliyahu M. Goldratt is a business novel that introduces the Theory of Constraints. Through the story of a struggling plant manager, you'll explore how identifying and addressing bottlenecks can dramatically improve efficiency and profitability. This book offers practical insights into managing and improving production systems, making it a valuable read for anyone interested in business process optimization.

About the Author

Eliyahu M. Goldratt was an Israeli physicist turned management guru known for his influential business novel "The Goal." His writing style blends storytelling with practical business insights, offering a unique perspective on operations management and the Theory of Constraints. Through his work, Goldratt emphasizes the importance of identifying and overcoming bottlenecks in business processes to achieve optimal efficiency and success.

10 Key Ideas of The Goal

Identify and Strengthen Your System's Bottlenecks

Focus on identifying the constraints within your system that are limiting its overall performance. Once identified, allocate resources and efforts to improve the efficiency of these bottlenecks. This approach ensures that you're not wasting resources on optimizing parts of the system that won't significantly impact the overall throughput. By systematically addressing each bottleneck, you can incrementally increase the flow and productivity of the entire system.

Learn DeeperIdentify Your Bottlenecks: Start by observing your daily routines or work processes. Look for stages that consistently slow down progress. This could be anything from a slow computer, a particular skill you lack, or even a time-consuming task that doesn't add much value.

Prioritize and Plan: Once you've identified your bottlenecks, prioritize them based on their impact on your overall productivity. Create a plan to address the most critical ones first. This might involve setting aside time to learn a new skill, upgrading equipment, or delegating tasks that are not essential for you to do personally.

Implement Solutions: For each bottleneck, implement a solution aimed at reducing its impact. This could mean setting specific times to check emails instead of constantly being interrupted, automating repetitive tasks, or creating a more organized workspace to reduce time spent searching for items.

Monitor and Adjust: After implementing changes, monitor the results closely. If you see improvement, great! If not, reassess and adjust your approach. Remember, the goal is to make continuous, incremental improvements, not to achieve perfection overnight.

Repeat the Process: Over time, new bottlenecks will emerge as others are resolved. Make this process of identification, prioritization, solution implementation, and monitoring a regular part of your routine to continuously improve your productivity.

- Example

If you're a writer and find that research takes up most of your time, making it difficult to actually write, the bottleneck is the research phase. To address this, you could set specific research hours, use more efficient research methods, or outsource some of the research work.

- Example

In a small business, if the order fulfillment process is slow because orders are processed manually, this is a bottleneck. Implementing an automated system to handle orders can significantly speed up the process, allowing the business to serve more customers and generate more revenue.

Adopt a Holistic View of Production Processes

Understand your operation as an interconnected system rather than a collection of independent processes. This perspective helps in recognizing how changes in one part of the system can affect others. A holistic view encourages collaboration across different departments and fosters a culture where everyone works towards the common goal of improving the system's overall performance, rather than optimizing individual metrics that may inadvertently hinder other processes.

Learn DeeperMap Out Your Processes: Start by creating a visual map of your production or work processes. This can be as simple as drawing on a whiteboard or using flowchart software. Include every step, no matter how small, and identify where different departments or teams intersect.

Identify Bottlenecks and Dependencies: Look for areas where work tends to pile up or slow down significantly. These are your bottlenecks. Also, note where processes depend on the completion of tasks in other departments. Understanding these dependencies is key to optimizing the whole system.

Implement Regular Cross-Departmental Meetings: Schedule meetings that bring together representatives from different departments to discuss ongoing projects and challenges. Use these meetings to share insights from the process map and collaboratively find solutions to improve flow and reduce bottlenecks.

Adopt Shared Metrics: Instead of evaluating departments on isolated metrics, develop performance indicators that reflect the health and efficiency of the entire system. This encourages teams to work together towards common goals, rather than optimizing their individual outputs at the expense of others.

Foster a Culture of Continuous Improvement: Encourage everyone in the organization to suggest changes that could improve the overall system. Make it clear that every role has the potential to impact the bigger picture and that collaboration is key to success.

- Example

In a manufacturing plant, the assembly line might be identified as a bottleneck because it can't keep up with the pace of the parts being supplied. A holistic approach might involve cross-training employees from other departments to help during peak times, ensuring the assembly line keeps moving efficiently.

- Example

In a software development company, the deployment of new features might depend heavily on the QA (Quality Assurance) team's availability. By mapping out the process, the company realizes that aligning the development cycle more closely with QA availability can reduce downtime and speed up the release of new features.

Implement Continuous Improvement Practices

Embrace the philosophy of ongoing improvement by regularly evaluating and adjusting processes. Encourage feedback from all levels of the organization to identify inefficiencies and areas for enhancement. This iterative process promotes a proactive culture of innovation and adaptability, ensuring the system remains efficient and competitive over time.

Learn DeeperStart with a Process Audit: Take a day to map out the key processes in your work or personal projects. Identify where delays, bottlenecks, or inefficiencies occur. This visual representation will help you see where improvements can be made.

Implement Regular Feedback Loops: Schedule monthly or quarterly feedback sessions with your team or peers. Use this time to discuss what's working and what's not. Encourage open and honest communication to surface issues and ideas for improvement.

Adopt the 'Five Whys' Technique: When a problem arises, ask 'why' five times to get to the root cause. This method can uncover deeper issues that, when addressed, prevent the problem from recurring.

Set Small, Incremental Goals: Instead of overhauling processes all at once, aim for small, manageable improvements. Celebrate these milestones to motivate continued progress towards enhancing efficiency.

- Example

A software development team conducts a process audit and identifies that their code review process is a bottleneck. They decide to implement pair programming to reduce the review backlog and improve code quality through real-time feedback.

- Example

A small business owner gathers feedback from her customers and learns that the checkout process on her website is confusing. She decides to simplify the checkout process and adds a FAQ section based on common questions, significantly reducing customer drop-off rates.

Prioritize Inventory Reduction

Excessive inventory can hide production issues and tie up valuable resources. Aim to reduce inventory levels without compromising on customer satisfaction. Lower inventory levels force the identification and resolution of production bottlenecks, leading to a more streamlined and cost-effective operation. This strategy also improves cash flow and reduces storage costs.

Learn DeeperAssess Your Current Inventory Levels: Start by taking a thorough inventory of your current stock. Identify items that are overstocked or have been sitting in storage for an extended period. This will help you understand the scale of inventory reduction needed.

Implement Just-In-Time (JIT) Inventory Management: Adopt a JIT approach, where materials and products are ordered and produced only as needed. This reduces excess inventory, minimizes storage costs, and ensures products are fresh and up-to-date.

Identify and Address Bottlenecks: Analyze your production process to identify any bottlenecks that slow down operations. Once identified, focus on resolving these issues to improve flow and reduce the need for holding large amounts of inventory.

Improve Forecasting Accuracy: Work on improving the accuracy of your sales forecasts. Better forecasting helps in ordering just enough inventory to meet demand without overstocking, thereby reducing excess inventory levels.

Regularly Review Inventory Practices: Make inventory review a regular part of your business practice. Adjust your strategies based on sales trends, seasonal demands, and changes in the market to keep inventory levels optimized.

- Example

A small clothing retailer notices that certain styles of clothing are not selling as quickly as anticipated, leading to an overstock situation. By implementing a JIT inventory system, they start ordering smaller quantities more frequently based on current sales trends, reducing their excess inventory and storage costs.

- Example

A manufacturing company identifies a bottleneck at one of its assembly lines, which causes delays and requires them to keep higher levels of inventory to meet customer orders. By reorganizing the workflow and adding additional resources to the bottlenecked area, they manage to streamline the production process, allowing them to reduce inventory levels while still meeting customer demand.

Deeper knowledge. Personal growth. Unlocked.

Unlock this book's key ideas and 200+ more. Learn with quick, impactful summaries.

Read Full SummarySign up and read for free!

The Goal Summary: Common Questions

Experience Personalized Book Summaries, Today!

Discover a new way to gain knowledge, and save time.

Sign up for our 7-day trial now.

No Credit Card Needed

Similar Books

Start-up Nation

Dan Senor

The Founder's Dilemmas

Noam Wasserman

Traction

Gino Wickman

Tribes

Seth Godin

Management 3.0

Jurgen Appelo

Only the Paranoid Survive

Andrew S. Grove

Execution

Larry Bossidy

Reinventing Organizations

Frederic Laloux

The Ideal Team Player

Patrick M. Lencioni

Multipliers

Liz Wiseman

Team of Teams

General Stanley McChrystal

The Toyota Way

Jeffrey LikerTrending Summaries

Peak

Anders Ericsson

Never Split the Difference

Chris Voss

Smart Brevity

Jim VandeHei

The Psychology of Money

Morgan Housel

The First 90 Days

Michael D. Watkins

Atomic Habits

James Clear

Thinking, Fast and Slow

Daniel Kahneman

The Body Keeps the Score

Bessel van der Kolk M.D.

The Power of Regret

Daniel H. Pink

The Compound Effect

Darren Hardy

How to Win Friends & Influence People

Dale Carnegie

Eat That Frog!

Brian Tracy

The Magic of Thinking Big

David J. Schwartz

Drive

Daniel H. Pink

Essentialism

Greg McKeownNew Books

Lean Analytics

Alistair Croll

Built to Sell

John Warrillow

Traction

Gabriel Weinberg

Start-up Nation

Dan Senor

Trump

Donald J. Trump

Crushing It!

Gary Vaynerchuk

Bold

Peter H. Diamandis

UNSCRIPTED

MJ DeMarco

The Innovators

Walter Isaacson

The Millionaire Fastlane

MJ DeMarco

Losing My Virginity

Richard Branson

Venture Deals

Brad Feld

48 Days to the Work You Love

Dan Miller

Anything You Want

Derek Sivers